By Jolly Kabirizi

Intensive poultry production systems cause serious waste management problems. Poultry waste includes faecal and urinary matter, bedding, wasted feed, feathers and non-degradable materials.

Poultry waste are non-consumable by humans, but could be recycled into low-cost livestock feed, thus entering the human food chain.

Recycling available nutrients for reuse in animal production, rather than disposing of them, would go a long way in reducing the final volume of animal waste released into the environment.

In addition, effective use of animal waste resources might provide a partial, but important contribution to reducing carbon oxide emissions.

Yield of poultry waste

When birds are housed on a littered floor, the amount of poultry house waste (litter) may be twice that of droppings alone.

It has also been estimated that for every kilogramme of egg mass produced, a hen produces about 4kg of fresh droppings or 1kg of dry excreta.

Processing poultry waste/litter

Poultry waste is a source of odour caused by the activity of anaerobic microorganisms in the manure.

It is, therefore, necessary to subject poultry manure to some treatments to improve its storage and handling properties and to minimise the risk of disease transmission and environmental pollution.

Proper poultry manure management systems that will preserve the environment — contribute to both animal and human health — and return a profit on investment to farmers, need to be developed.

Processing methods are helpful in detoxification, improving its feeding value, palatability and texture/colour.

Good poultry waste management, such as excluding dead birds/other extraneous materials from the litter and appropriate processing before feeding, such as sun-drying, ensiling or roasting, has been reported to prevent the growth of microorganisms.

Sun-drying

Dried poultry waste is feasible, because it contains less moisture than that in pig or cattle excreta.

Poultry manure can be sun-dried and used in animal feeding. Sun-drying reduces the bulk of animal waste to 20%-30% of the original volume.

By drying, the rate of deterioration from chemical and biological activity is minimised and the environmental problems associated with raw manure are prevented.

Drying also removes manure stickiness and hence allows for easier handling.

Savings in feed cost through nutrient recycling would be sufficient to justify the cost of sun-drying while also protecting the environment.

The best poultry manure is that collected from caged birds, sieved and sun-dried.

Drying in a homemade solar dryer

Using a homemade solar dryer designed similar to a greenhouse (using plastic covering) can be used to dry the poultry waste.

The solar dryer reduces the weight to about 72% of the original input.

Safety is fairly good; much depends upon the temperature and time of exposure, but most potentially, dangerous microbes are usually eliminated.

Dry poultry waste is sieved to remove foreign materials, such as feathers and stones. The dry matter is milled into powder using a mill hammer, which is then stored in a well-ventilated store.

Ensiling

Ensiling (to prepare and store — fodder/feed — to induce conversion to silage) processed poultry waste improves, not only its palatability, but also destroys pathogens.

Poultry manure or litter can be ensiled with crop residues, such as maize stover, rice straw, sweet potato vines, and bean husks; forages and other roughages with diluted molasses alone provided there is sufficient moisture (40-60%) and soluble carbohydrates in the substrate to ensure good fermentation process.

The ratio of crop residues or other roughages to poultry waste is adjusted to obtain a minimal moisture content of about 40%; moisture should not exceed 70%.

Molasses (1%–3%) or other sources of fermentable carbohydrates must be added if sufficient soluble carbohydrates are not present in the ingredients for ensiling.

Ensiling is a simple process, which not only prevents the losses on a total crude protein content, but also converts part of the non-protein nitrogen into protein-bound protein (true protein).

Ensiled poultry waste is nutritionally superior to the dried product.

Feeding processed poultry waste to livestock

Poultry-pig-fish integration

- An integrated layer/pig/fish cycle is the most advanced and economically sound recycling system with zero pollution discharge. Cages for laying hens are constructed for laying hens 1.5 metre above the pig pen, thus saving the cost of a poultry house.

Excreta from laying hens fall down into the pen, where it is consumed by pigs within seconds. One pig is usually “serviced” by three to seven birds, and the pigs receive 6.3%–14.6% of layer manure (dry matter) in their ration.

The disadvantage of this system is that smaller pigs consume more manure than larger pigs, while the reverse should be true.

Dry matter intake of layer manure by pigs is about 10% of the total feed. In this system it is imperative to formulate pig rations carefully in order to avoid imbalances in calcium and phosphorus.

No negative effects on the production or health of pigs has been observed. This system, when complemented with fish, represents a completely closed zero[1]pollution cycle.

- Dairy cows Research conducted on feeding processed poultry waste to dairy cows showed encouraging results with no adverse effects on milk yield or composition.

The optimum level of poultry waste in dairy cows’ ration has been worked out to be 15% in high yielding animals to prevent excessive intake of calcium, which may otherwise cause serious metabolic disorders.

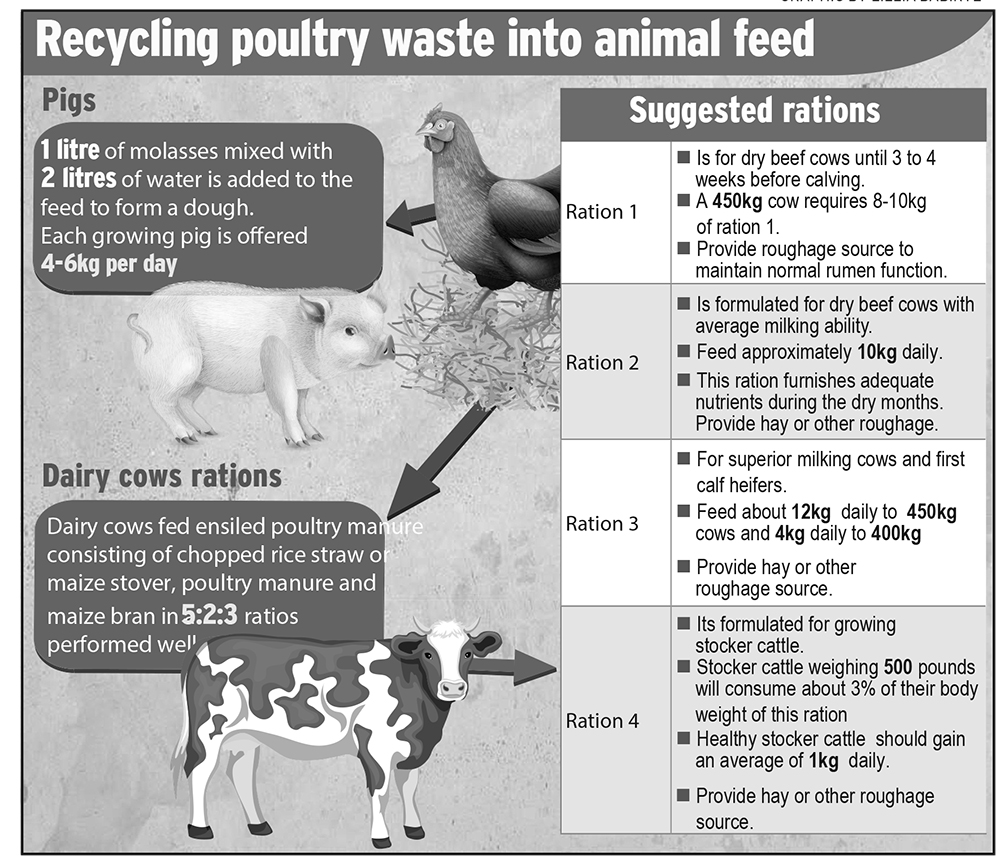

Dairy cows fed on ensiled poultry manure, consisting of chopped rice straw or maize stover, poultry manure and maize bran in a 5:2:3 ratios performed well. Cows usually adapt themselves rapidly from fresh green forage or pasture to the poultry litter and cassava silage without any adverse effect on milk production.

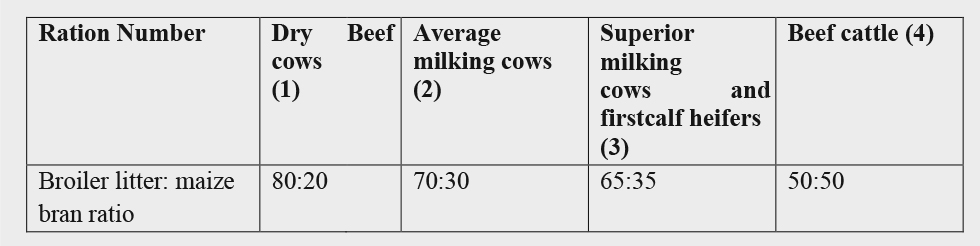

- Feeding broiler litter to beef cattle Broiler litter as an alternative feedstuff may become more widespread as the need for economy in agriculture and for responsible waste management becomes more urgent.

Broiler litter, as a cattle feed, offers three primary advantages:

- It is an environmentally responsible use of a by-product

- It provides an incentive for the proper management of the by-product by poultry and cattle producers

- It economises the production of beef cattle.

Composition of poultry waste

The protein content in the dried poultry manure is 25%-30%, equivalent to 75% of three grades of fish meal protein matter content.

Poultry waste contains plant nutrients, such as nitrogen, phosphorus and potassium. It also contains trace elements, such as copper and zinc and pesticide residues.

It also has pharmaceuticals, such as coccidiostats, endocrine disruptors and microorganisms.

From a hygiene perspective, unprocessed poultry waste contains potential pathogenic microorganisms, such as clostridium, salmonella and enterobacter spp.

Therefore, proper processing to reduce the number of these microorganisms or render the waste free of pathogens is required.

In addition, feed additives, such as antibiotics, arsenicals and coccidiostats are added to poultry diets, which can be excreted as waste by-products.

Also, some of the fungal species that are indigenous to the manure or litter can result in the production of mycotoxins. Pathogenic microorganisms can be destroyed by chemical, fermentation, ensiling or heat processing.

Feeding poultry waste to pigs

At Kyakuwa Farm (Bunnamwaya site), Wakiso district, a layer of coffee husks is spread on the floor under the cages to allow the droppings to fall on them and not directly on the floor.

This keeps the floor clean and ensures that the poultry waste collected is clean. The poultry waste mixed with coffee husks is dried in a solar dryer for three days and milled into powder.

A feed ration, comprising of well-dried sieved poultry waste (powder), maize bran, common salt, vitamin premix and fish meal, is fed to growing pigs.

At feeding time, one litre of molasses, mixed with two litres of water, is added to the feed to form a dough. This reduces the wastage of the feed.

Each growing pig is offered 4- 6kg/day, depending on the age and weight. Half the mixture is offered to the pigs at 8:00am and the other half at 2:00pm. The feed ration reduces the cost of feeding pigs by over 30%.

Suggested rations

The two deficiencies associated with litter and grain mixes are vitamin A and fibre.

Add vitamin A to litter and grain mixes or inject individual cattle. Provide hay, pasture, maize stover or some other roughage to meet fibre needs.

To obtain the desired animal performance, adjust litter to grain ratios and feed consumption. Maize is usually the preferred grain to mix with litter.

However, other high-energy/low-protein concentrates, when properly processed, may be used, such as soybean hulls.

- Ration 1 is for dry beef cows until 3 to 4 weeks before calving. A 450kg/ dry cow requires 8-10kg of Ration 1 during the dry months. Provide roughage source to maintain normal rumen function.

- Ration 2 is formulated for dry beef cows with average milking ability. Feed approximately 10kg daily. This ration furnishes adequate nutrients during the dry months. Provide hay or other roughage.

- Ration 3 is formulated for superior milking cows and first calf heifers. Feed about 12kg daily to 450kg cows and four daily to 400kg first calf heifers. Provide hay or other roughage source.

- Ration 4 is formulated for growing stocker cattle. Stocker cattle, weighing 500 pounds, will consume about 3% of their body weight of this ration. Healthy stocker cattle that have been dewormed, vaccinated, implanted and otherwise managed as recommended should gain an average of 1kg daily when fed this ration. Provide hay or other roughage source.

The writer holds a Phd in Animal Science